Spray Finishing Problems: Orange Peel

In this, my second part 2 of my four-part mini-series on spray finishing problems, I’ll be focusing on orange peel. And as promised in my previous article, I’ll use my three-step problem resolution process. Let’s get at ‘er!

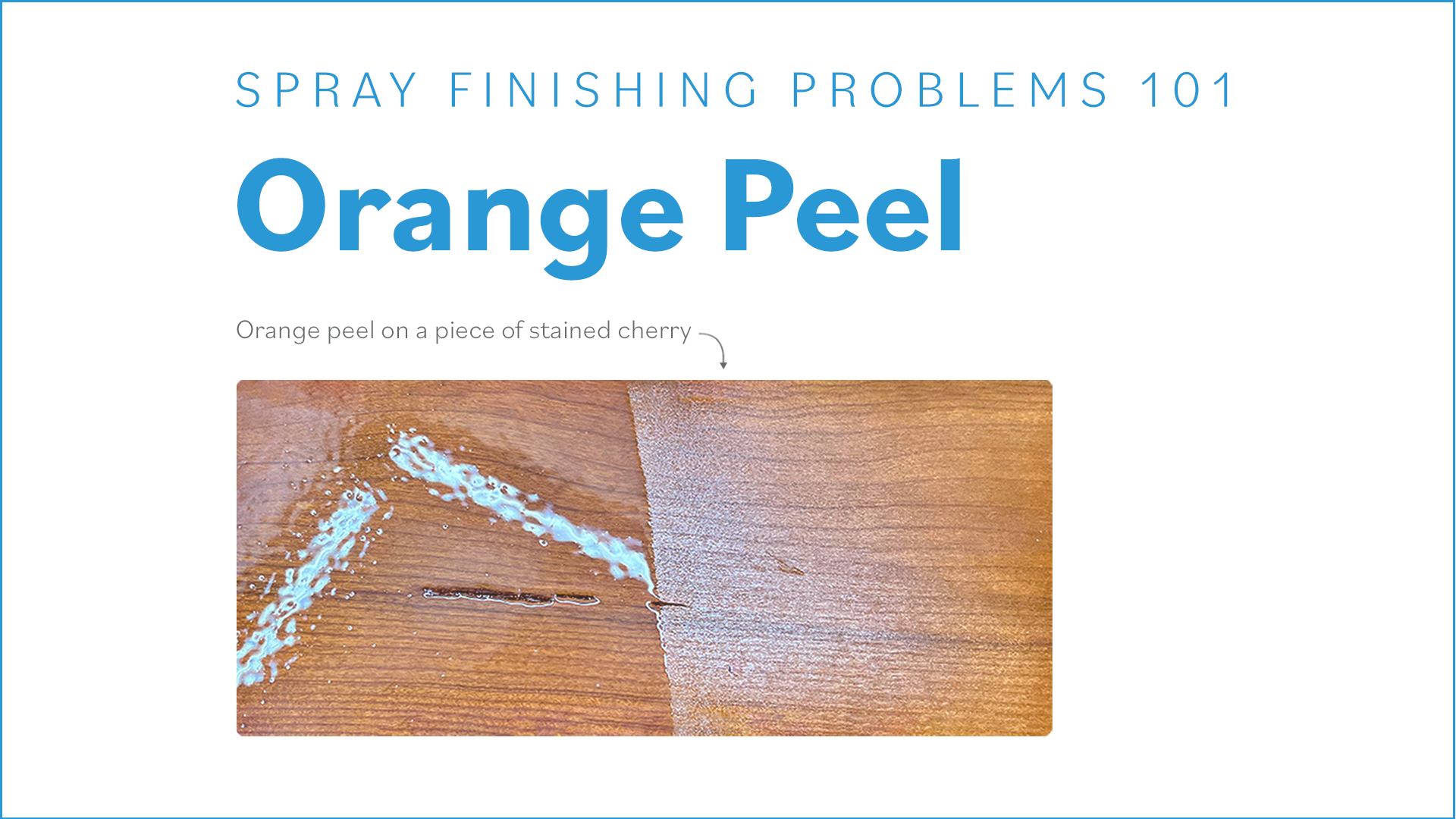

1. Identifying Orange Peel

If the surface looks and feels like the surface of an orange (hence the name) it’s undoubtedly orange peel. And it’s certainly something you’ll need to fix!

2. Dealing with Orange Peel

Sorry to be the bearer of bad news, but the best way to deal with orange peel is to sand the piece until the orange peel has been sanded out and the piece is once again flat, then reapply the finish.

Depending on the degree of orange peel, you may not have to resort to going all the way down to P80 grit sandpaper. Start with the least aggressive grit size that does the trick, then work your way up to P400 or whatever grit the finish manufacturer recommends for the finish you were using.

And a word of caution:

don’t sand through to bare wood, or even the seal coat if you can help it, as you’ll only make more work for yourself.

3. Understanding the Cause(s) of Orange Peel

There are three possible causes, so it’s important to determine which one is the culprit to keep it from recurring. And by the way, in some cases, it can be any one or a combination of them!

Incorrect spray gun adjustment.

In 90% of all cases, improper spray gun adjustment is the cause. If you have misadjusted your spray gun by allowing too much finish for the amount of air, the finish particles cannot be broken down into the small droplets necessary for producing a smooth coat.

To learn how to efficiently atomize, properly adjusting your spray gun’s settings is a must!

Incorrect finish viscosity.

This particular challenge is caused by your finish being too viscous (think: thick as molasses in January), making it difficult, if not impossible for your spray gun to properly atomize the finish. In certain cases, a change in aircap set may be in order. Regardless, in all cases, check the TDS (Technical Data Sheet) to determine the type(s) and amount of thinners allowable, then make the necessary correction.

What I also recommend is documenting the thinning information once you’ve confirmed the values that work. And once you’ve correctly adjusted the viscosity, don’t forget to go back and reset your spray gun’s fluid-to-air balance.

Excessive finish.

This cause isn’t as common as the previous ones, but if you’ve tried everything else and are still getting orange peel, review the finish manufacturer’s recommended wet film thickness for each coat (such information can be found in the TDS). Because film thickness can affect the leveling out, bonding and curing process, it’s important that you follow the manufacturer’s thickness recommendation.

And until you’ve become familiar with what the correct wet film thickness looks like right after being sprayed, you need to figure it out by using a wet film gauge.

Summary

Spray finishing is one of the most efficient, flexible, and consistent methods for achieving the highest finish quality. But that doesn’t mean you won’t run into finish problems. I’m hoping that this mini-series on finish problems will keep them from happening to you and help get you back on track whenever they trip you up.

Stay tuned for the installment in this mini series of spray finishing problems — focusing on striping. As always, let me know if you have any questions or comments on this topic, or if there’s another topic you’d like me to write about, let me know. I’m here for you.