How to Spray Acrylic Paints

If there’s one thing my several decades as a furniture and cabinetry designer-maker have taught me, it is the importance of being responsive to new information.

Follow along as we explore modified techniques on how to spray acrylic paints with turbine HVLP systems and achieve pro-level results. Let’s go!

Product selection and pre-priming

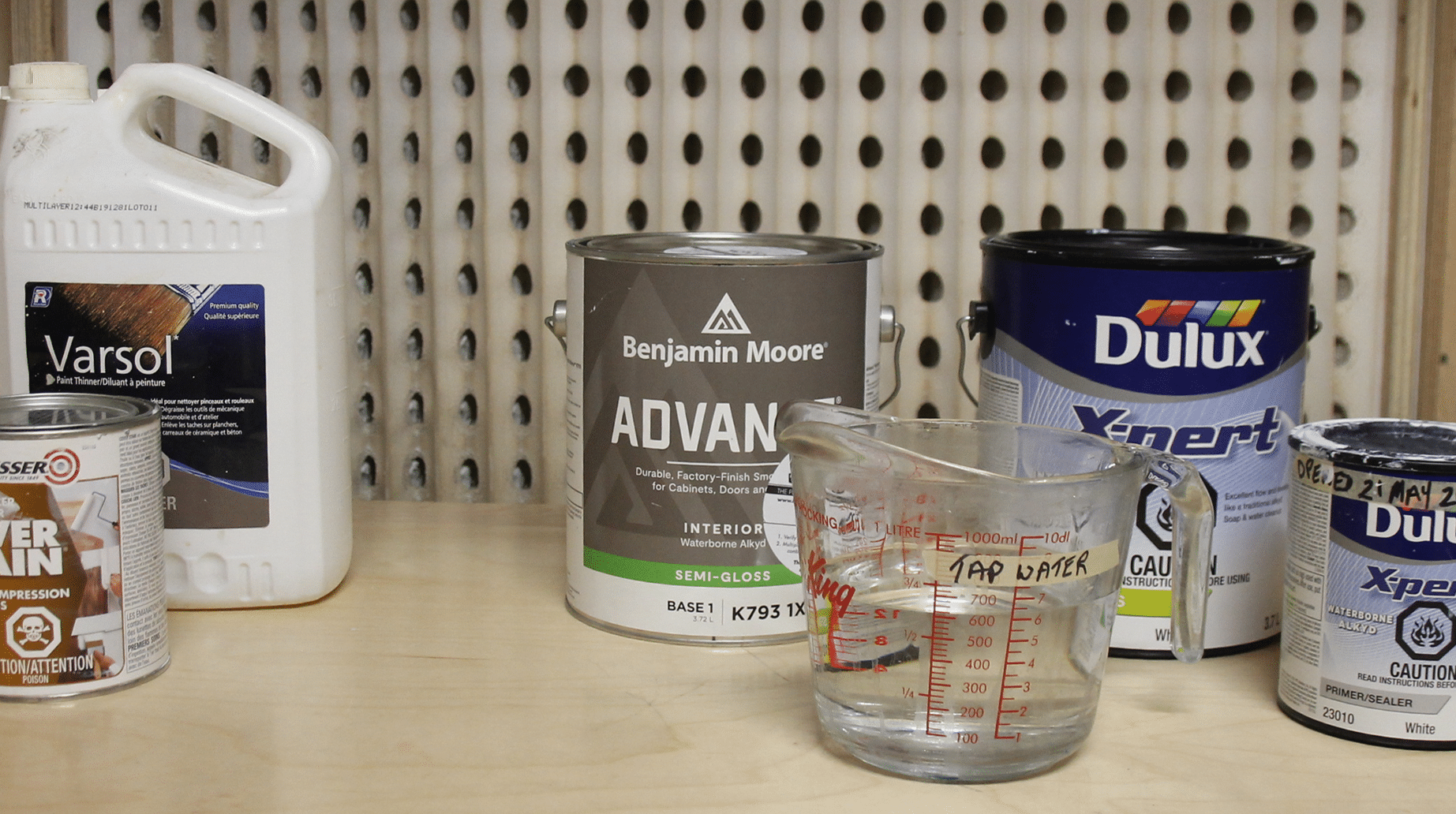

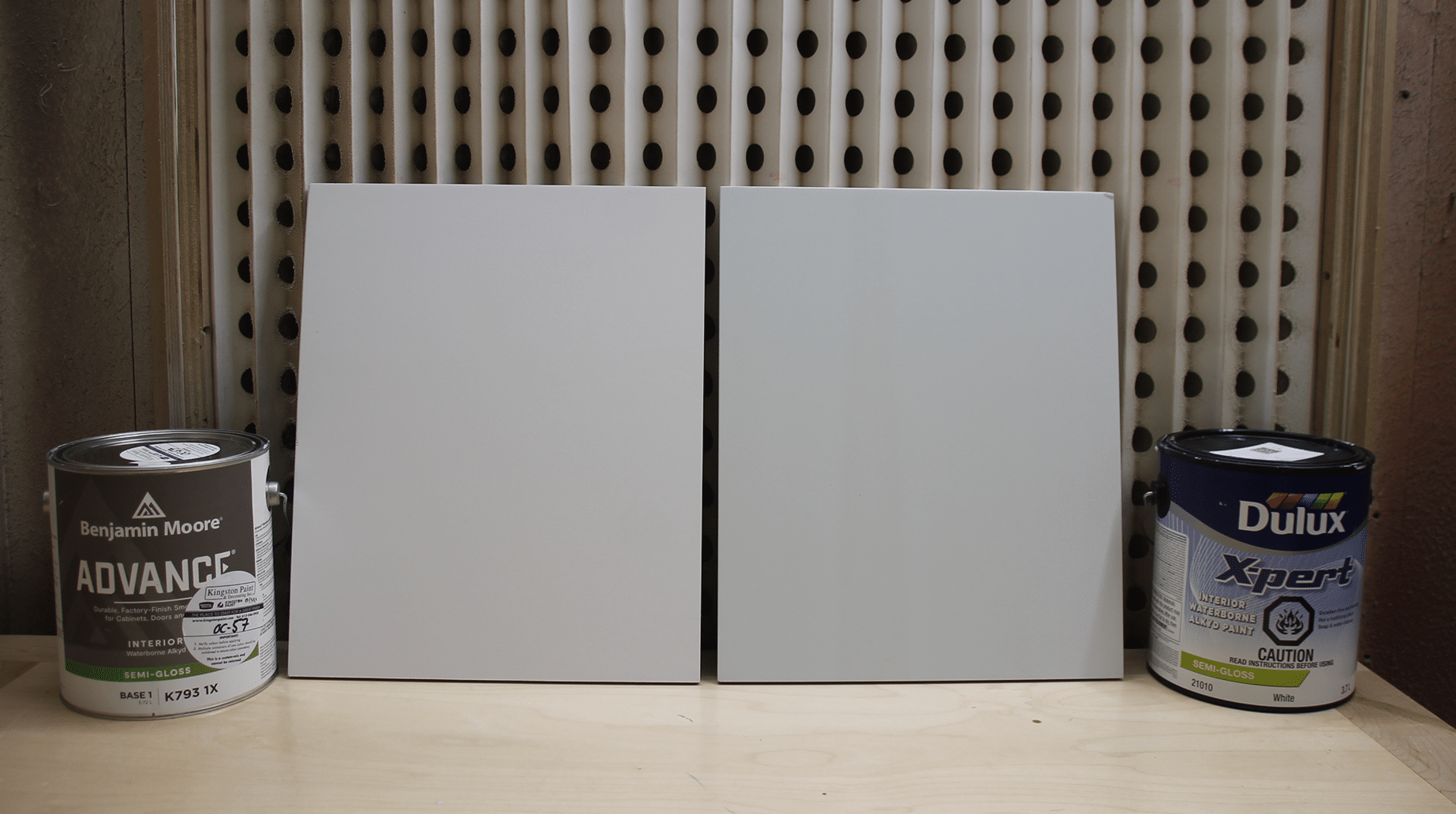

To begin, I’ve selected two of the most popular acrylic paints: Advance by Benjamin Moore and X-pert by Dulux.

Additionally, as the test panels I prepared for this article lacked any finish, I decided to pre-prime them. Pre-priming is essential to ensure proper bonding when working with bare wood. Following my local suppliers’ recommendations, I selected the following primers: Zinsser Cover Stain primer-sealer for the Advance and X-pert Primer/Sealer for X-pert.

Thinning and additives

Right out of the tin, acrylic paints are naturally viscous (thick). Therefore, thinning these high-viscosity paints is necessary for spraying with HVLP equipment. My hard-earned advice on thinning any finish stands:

only thin when necessary, and with as little thinner as necessary.

Thinning primers

I thinned the Zinsser oil-based primer-sealer with varsol at a 10:1 ratio. Similarly, the Dulux water-based primer-sealer was thinned with tap water at the same 10:1 ratio. It’s important to note that the oil-based primer had a significantly lower viscosity reading of 40 seconds on the Ford 4 cup, while the water-based primer had a higher viscosity reading of 85 seconds.

Thinning paints

My suppliers for these products cautioned about over-thinning, so I only went as far as a 10:1 thinning of Advance. The same thinning ratio was applied to the X-pert paint. Surprisingly, both thinned products came out with a Ford 4 viscosity reading of 100 seconds. This reading was considerably higher than the usual range of 35 to 40 seconds that I recommend for spraying with turbine HVLP equipment.

Special recommendation for 2 & 3 stage turbine owners

Thinning beyond the recommended 10:1 level will most likely be necessary. I’d therefore suggest starting at 9:1 thinning, and if that proves challenging for your equipment, try a thinner mixture of 8:1.

Avoid applying Floetrol to Advance

Following the advice of my local Benjamin Moore supplier against any additives for Advance paint, I decided to follow that advice when thinning both paints. I’m glad I did, as on some of the test panels I’ve seen in both my own shop and during the workshop training I’ve conducted, I noticed the presence of micro-bubbles sometimes appeared on the cured finish when additives were used. Leaving out that additive helped me achieve the pro-level results I had been looking for.

Lesson learned: Follow the advice of your finish supplier!

Spray gun set up

Select a 2.0 aircap set

Although I have usually recommended either a 1.8 or 1.8mm aircap set for spraying acrylic paints. Due to the higher viscosity of all but the oil-based primer, I elected to go with a 2.0 set.

Adjust your spray gun

To accommodate the higher viscosity of these finishes, I narrowed the fan to 8” in height, which is somewhat less than I usually recommend. By narrowing the fan, I concentrate the atomizing air into a smaller area. This is a trick I learned, which has helped me achieve pro-level results with my turbine HVLP system.

Additionally, you’ll also have to adjust the fluid level as the smaller fan requires less fluid. But don’t be surprised if the droplets at the edges of your fan pattern appear larger than usual, as this thinned finish is still very viscous. Aim to achieve a balance of optimal atomization (the process of breaking down a liquid into fine droplets or particles) and being able to lay down enough product on each path.

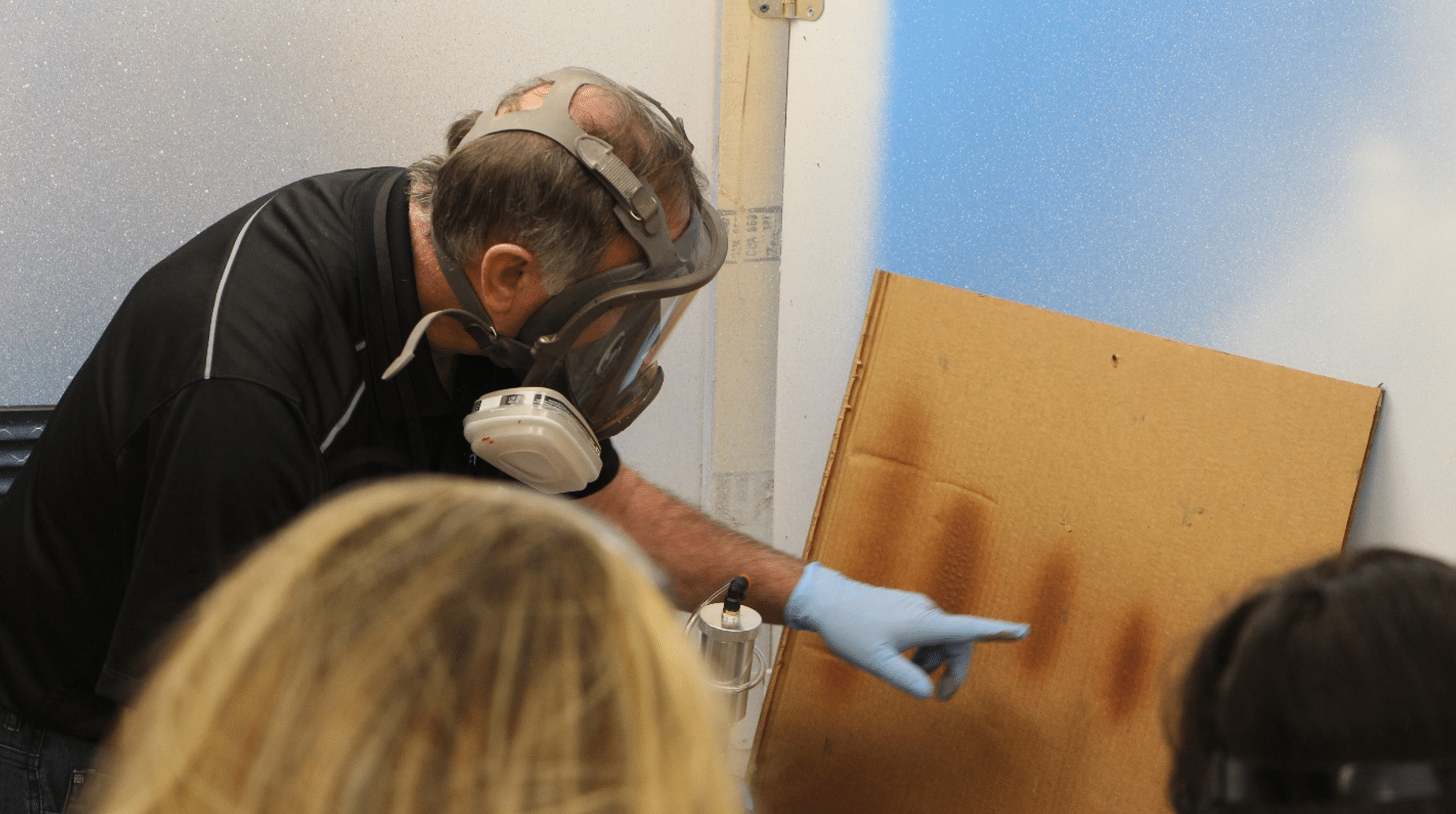

Panel spray test

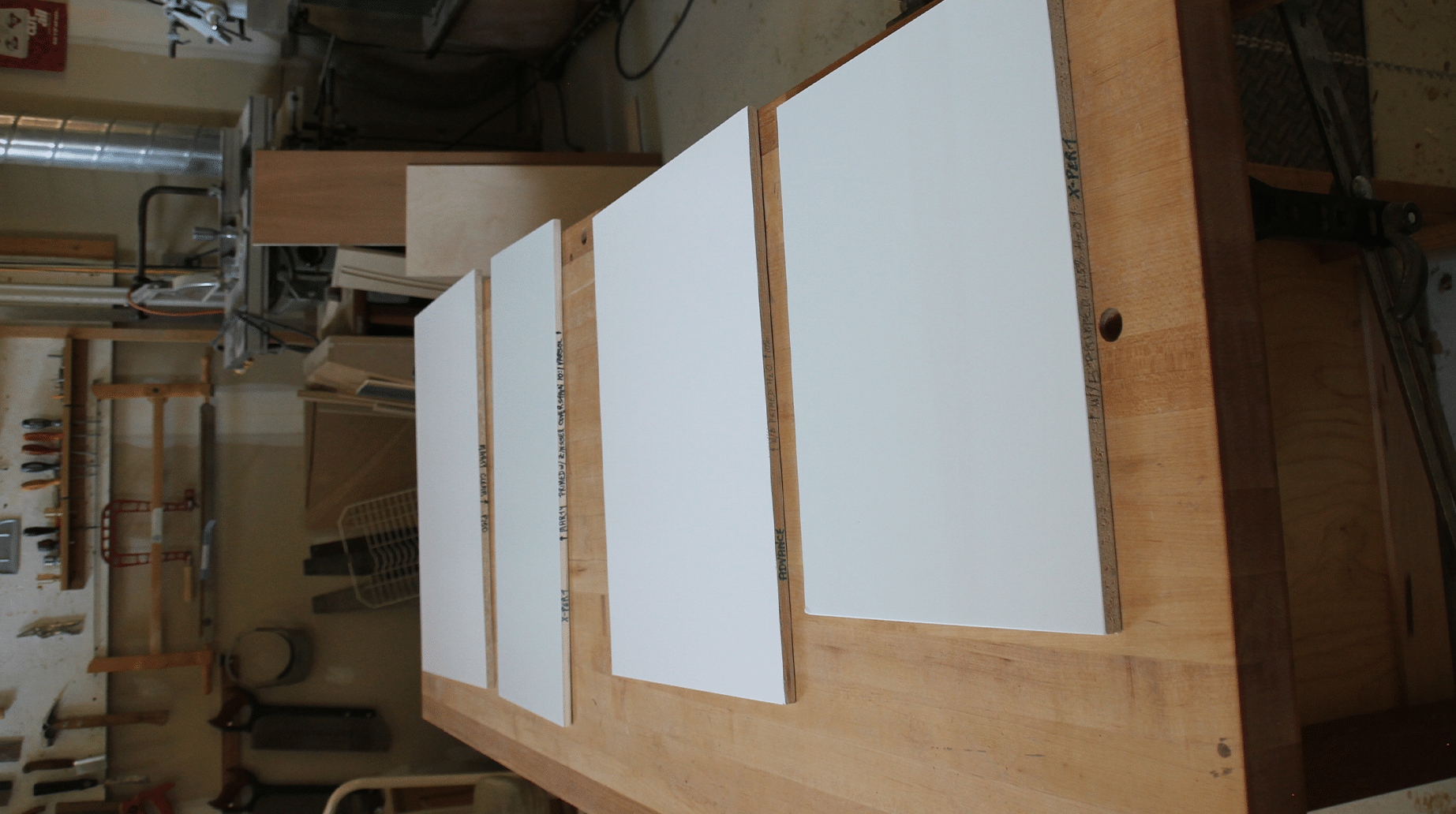

For the test, I prepared 4 panels: 2 were primed with the oil-based primer, and the other 2 were primed with the waterborne primer. I wanted to consider those who don’t have the luxury of a commercial spray booth with its explosion-proof fans and lighting, so I wanted to see how the waterborne primer would perform under both paints.

Using the same equipment (Fuji Spray’s Q5 Platinum turbine and Fuji Spray T75G spray gun with a 2.0 aircap set), I applied the manufacturer’s recommended single coat of primer to all the panels. I allowed 24 hours for the primer to dry and then used a random orbit sander with P180 sandpaper.

Once I made sure there was no sanding residue left, I then applied one single coat of paint, again, using the same equipment as used with the primer. I allowed 72 hours for the paint to dry fully before evaluating the final results.

Results

After visually inspecting and running my hands over the face of all four of them, I concluded that the 2 panels primed with the oil-based primer had small “nubs” over their entire surface. I requested my better half to do the same evaluation, and she agreed with my conclusion.

I then carefully assessed the surfaces of the 2 waterborne primed panels, and could not see, nor feel any difference between either the Advance or the X-pert painted surfaces. Both surfaces were flawless.

Summary

In a nutshell, here’s my recommendations for achieving pro-level results:

- On bare wood, start by applying a waterborne primer thinned at a 10:1 ratio with water

- Thin the acrylic paint at a 10:1 ratio with water

- Avoid using any additives

- For turbine HVLP systems:

- Mount a 2.0 aircap set

- Narrow the fan to 8” height and adjust the fluid level for optimal results

Good luck with your spraying and let me know what you think of my updated process!