Choosing HVLP Air Caps and Accessories

Many new HVLP spray gun users may not be familiar with air cap sets and accessories, and even some experienced users might not have explored different air cap sizes beyond what came with their gun.

Manufacturers usually make an educated guess when choosing the air cap size for their product, but as a consumer, it’s a good idea to experiment with different sizes. In most cases, using a 1.0mm needle and nozzle, which sprays clear finishes like lacquer and shellac beautifully, can be a great starting point, especially if you want a fine finish.

There’s an exception for thicker paints and tinted lacquers, where you’d want an air cap in the 1.5-2.0mm range. The general rule is that:

thicker coatings require a larger air cap size.

If you aim for the lower end of the recommended range, you’ll likely achieve a finer sprayed finish.

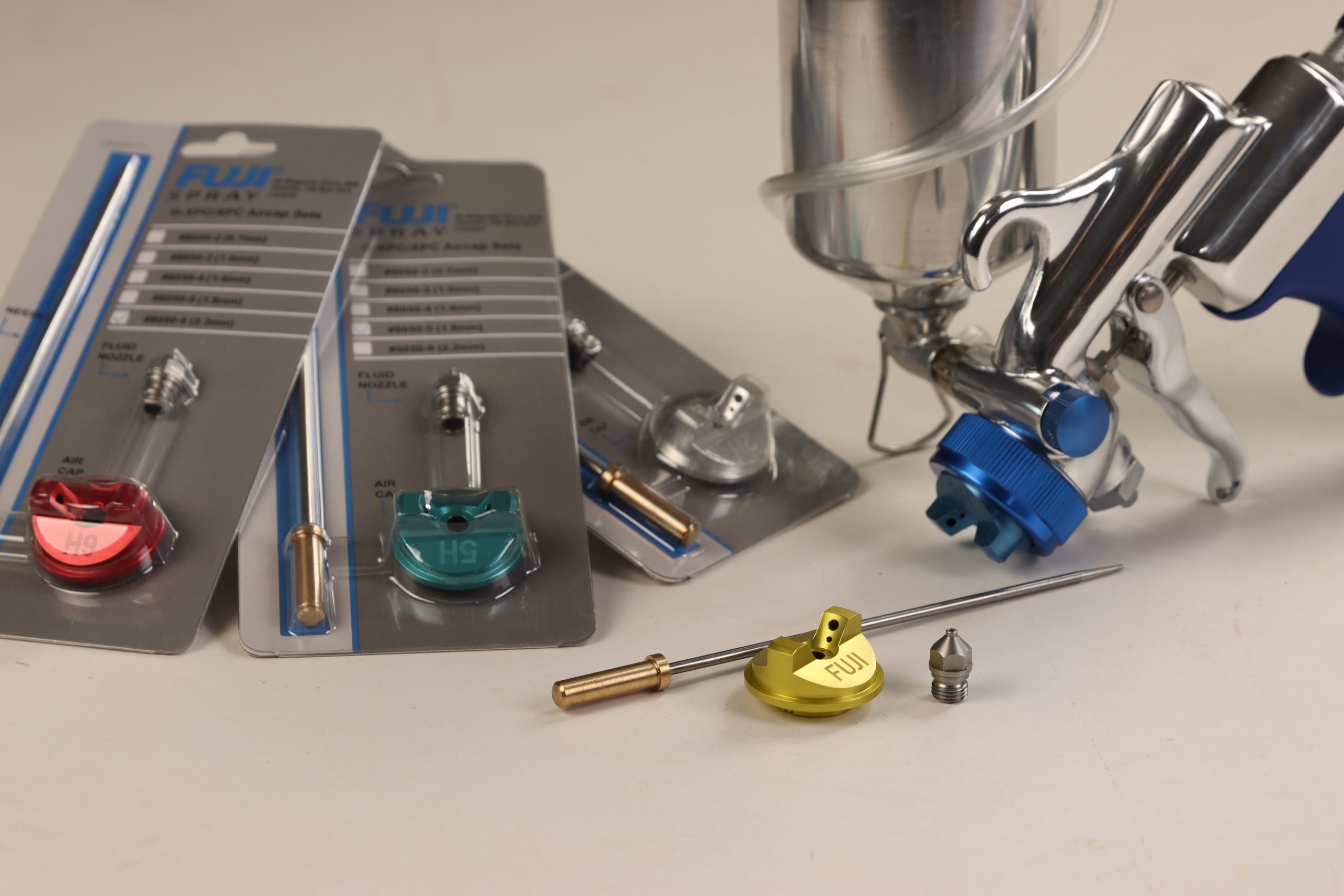

Air Cap Set Components

Every set comes with three essential components: a needle, a nozzle, and an air cap. These components are carefully matched to ensure the best spraying performance, so when you’re switching to a different size, make sure to replace all three parts.

It’s worth noting that the collar that holds the air cap is a separate piece and can be used with any size air cap.

Exploring Different Air Cap Sets

The G-XPC air cap sets are color-coded to help identify them at a glance.

Beyond their stated size, such as 1.0mm or 1.4mm, they also have code designations. If you see labels like 3H or 4H, don’t let it confuse you. This is just another name for air cap size. A 3H aircap is 1.0mm, and a 4H is 1.4mm.

You might also hear air cap sets described as “tips” or “needle and nozzle sets” and these terms all describe the same parts.

Notice the larger diameter of the needle shank at the back, which is a telltale sign you have a G-XPC needle.

The M-Model gun, shown in a gravity feed configuration, comes standard with a 1.3mm air cap set. If you primarily spray clear finishes, try a 1.0mm set.

You’ll be amazed at what a nice fine finish it produces. In fact, I consider a 1.0mm air cap set the #1 must-have accessory for furniture builders and cabinet makers.

There’s quite a variety of turbine-driven HVLP spray guns on the market.

From left to right, The M-Model in gravity feed and bottom feed configurations, the G-XPC side mount gravity feed, T-75G gravity feed, and T-70 bottom feed.

Note that all of these models feature pressure assist tubes and check valves, for continuous positive pressure.

Conversion Kits

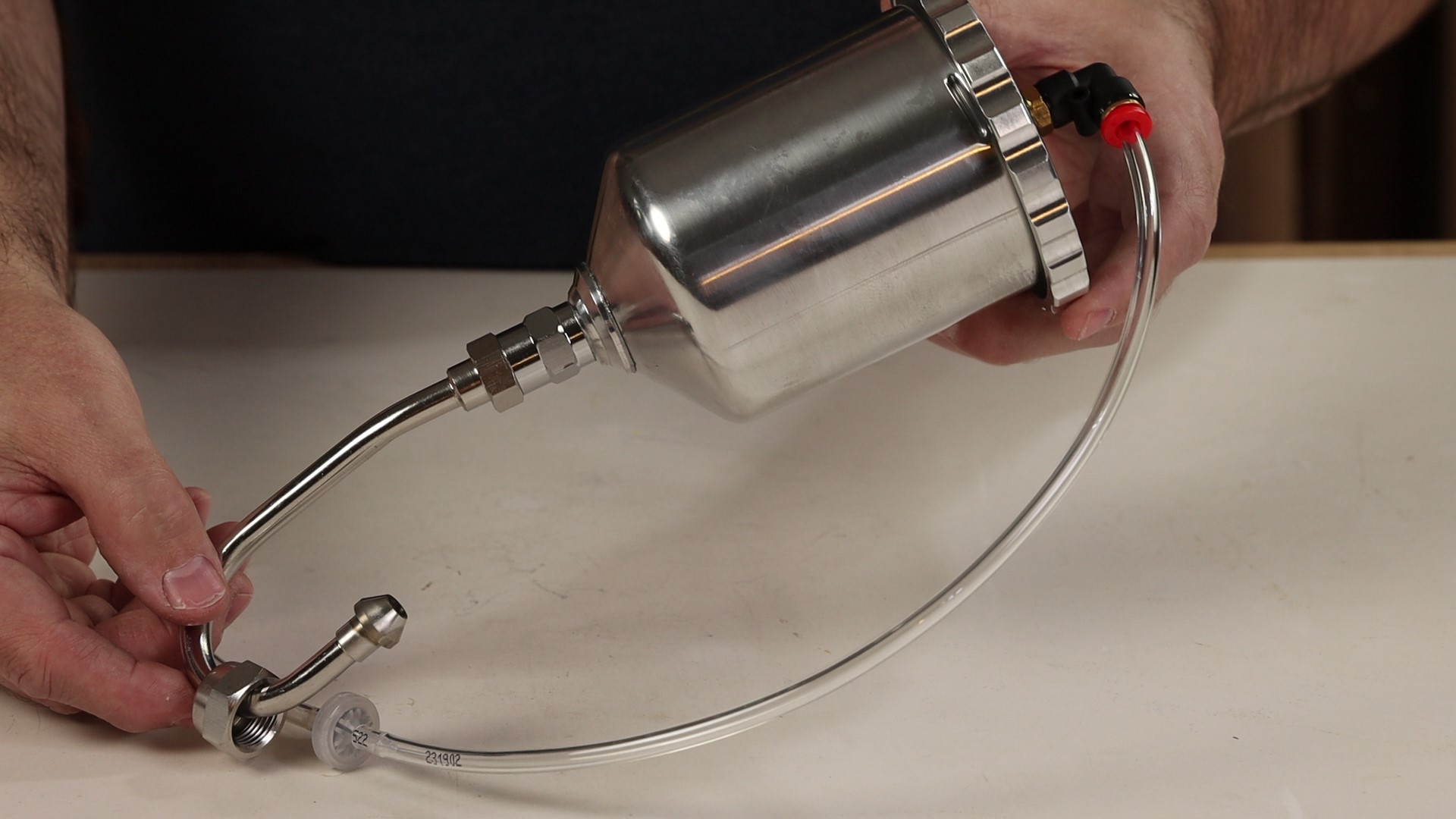

In addition to the M-Model gravity conversion accessory, there’s also a 600cc right-angle cup kit available for your G-XPC.

This accessory increases the original 400cc cup by 50%, letting you spray longer on those big jobs.

The kit comes with the nylon cup and lid (with pressure tube fitting), and a 90-degree swivel fitting. This hardware makes the new cup a direct bolt-on accessory for the G-XPC model.

Explore More HVLP Accessories

Once you use an HVLP gun with pressure assist, you’ll have a hard time going back.

The continuous positive pressure is controlled by a one-way check valve. This makes sure the pressure flows only from the gun body to the cup, and not back and forth. A pressurized cup also gives you more flexibility with the angle you spray.

In fact, a pressure-assisted gravity feed gun will spray at almost any common finishing angle.

If you truly need to spray with the gun inverted for extended periods, consider the 2Qt. pressure pot accessory.

Rounding out the list of HVLP gun accessories is a Ford viscosity cup.

Simply dip the cup into your coating and start a stopwatch. The time it takes to drain is an indication of the fluid thickness. This, in turn, tells you how much to thin the fluid before spraying.

For quick reference, you can check this guide for runout times of common products.