Advantages of HVLP Turbine Systems I

In my 20+ years of using turbine HVLP systems, I’ve discovered that they’re incredibly versatile and ideal for a wide range of woodworking enthusiasts and professionals alike, including furniture makers, cabinetmakers, luthiers, and general woodworkers. Businesses of all sizes have also recognized the benefits of turbine HVLP spray finishing equipment, as they can lay down a broad range of finishes that’ll stand up to the most discerning eye. With options available at various price points, turbine HVLP systems are popular among both beginners and seasoned professionals entering the world of finish spraying.

In this two-part article, I’ll delve into why turbine HVLP spray finishing systems have gained such a large following. Along the way, I’ll be dropping tips to help you get the most out of your spray finishing equipment. Part one will focus on two key characteristics: flexibility and portability.

In the second part, I’ll explore the ease of maintenance, low overspray, and where they fit into the production-level shop lineup. By the end of this two-part blog, you’ll be as sold as I am on turbine HVLP finishing systems.

Flexibility

1. Handles a Wide Variety of Finishes

There’s no one finish suitable for all woodwork. Whether you’re in the workshop or on a job site, your spray finishing system must be able to handle all the finishes you need to achieve pro-level finishing results. Some projects may require enhancing the natural tones and characteristics of the wood, while others demand complete color transformations for entire pieces or specific sections.

Most projects need a protective coating to lock everything in. Turbine HVLP systems excel at delivering this wide array of finishing options, ensuring versatility and quality results.

It always gives me goosebumps when I watch someone for whom I’ve made a custom piece of furniture, be amazed as they run their fingers over the finish. Even in the toughest conditions, sprayed finishes endure remarkably well over time, which is a game changer for woodworkers of all stripes.

PRO TIP!

Start first by selecting your desired finishing product from the many different types available. For guidance, refer to part one and part two of my blogs explaining the differences between seal coats, primers, colorants, and top coats. Once you’ve made your selection, select the right aircap and fine-tune your spray gun settings on your spray gun to achieve the best possible atomization with that product.

2. Choose from Several Finish Containers

Projects come in a variety of sizes and shapes, some of which require different volumes of finish application. It’s essential to equip your spray gun with a fluid container that matches the demands of each project, that’ll get the job done most efficiently. Turbine HVLP systems offer versatility in this regard, as they can mount or be connected to finish containers of various sizes and capacities.

Here are a few of my favorite options:

3M™ PPS™

This cup system is widely considered the Cadillac of cup systems, and for good reason. Not only does it allow you to spray in any orientation – upside down or sideways, for instance – but it speeds up the filling and cleaning process.

PRESSURE POT

For projects requiring substantial amounts of finish, such as kitchen cabinets or large tables, a pressure pot is the ideal choice. These pots can hold significant volumes of finish, relieving the strain on your arm by distributing the weight away from the spray gun.

SMALLER CUPS

Certain projects demand only a small quantity of finish, such as touch-ups, toning a piece to blending stains, crafting smaller items like jewelry boxes. For these projects, I mount one of the available smaller cups. And with bottom feed spray guns, there is the convenience of easily swapping out finishes (such as after spraying the sealer and moving onto laying down a topcoat) by unscrewing the cup from the spray gun and sealing it with a lid, eliminating the need to pour it back into the finish container.

3. Different HVLP Spray Guns

Having been in the industry for several years, I’ve accumulated a number of different spray guns at my disposal. Below, you’ll find a photo featuring four of my favorite models: the Touch Up, G-XPC, T70 with 3 oz cup, and T75G spray guns. Each of these guns offers unique advantages and functionalities, catering to specific requirements in various woodworking projects.

PRO TIP!

To keep your spray guns safe and easily accessible, consider storing them hanging from a wire shelf, as demonstrated in the above photo. This not only reduces the risk of damage but also ensures they’re always at arm’s reach when you need them. After cleaning and rinsing your turbine filter, place it on a wire shelf to dry, just as I’ve done here.

Investing in a second set of filters is highly recommended, especially for turbines that require a pair. This ensures you’ll have a clean filter readily available at all times. Additionally, rotating between sets regularly will prolong their lifespan, meaning you won’t need to purchase replacements frequently.

Portability

1. Consist of two main components

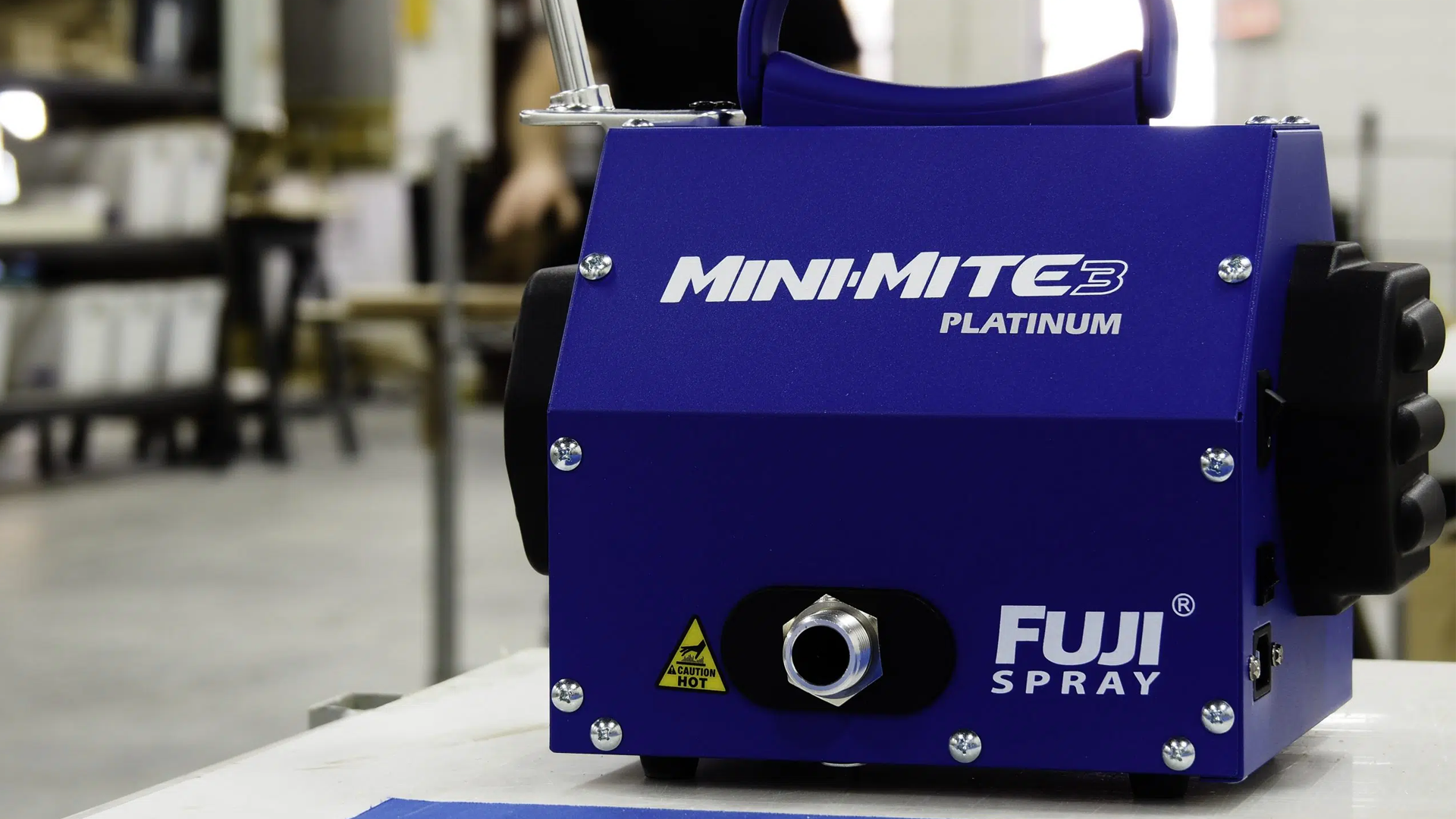

Turbine HVLP systems are most certainly one of the most portable of all spray finishing systems.

Although I have access in my shop to two other finishing systems, my turbine HVLP system is the one I’ll reach for the most. A huge part of that is because it’s so portable. It’s as simple as a compact and portable turbine paired with an HVLP spray gun, connected by an airline. No need for an air compressor with its chiller and dual filtration system. Plus, there’s no hassle of dealing with a lengthy 25′ fluid line that requires thorough flushing between finishes and at the day’s end. You’ll save by not losing finish while flushing that long line, too.

PRO TIP!

Adding a 4’ whip hose between your main air hose and spray gun will make it that much easier to maneuver your spray gun – as well as making it easier on the wrist.

2. Readily store your system away when not in use

Because your system is so portable and compact, for those of you with limited shop space, you’ll be encouraged to stow it away after each use. And speaking of storage cabinets, the photo below shows my arrangement: a shop-built cabinet which houses my turbine at floor level and offers drawers for stowing everything else. The top of the cabinet serves as a space for mixing finishes, too.

PRO TIP!

Disconnect your hose before stowing your system away to make it that much easier to move it around as well as for tucking into a cabinet. When you’re ready to take your system out from its storage cabinet, to keep the hose from kinking and limiting airflow, place the turbine on the floor and connect the hose. Never place it on a shelf unless you have some means of supporting the hose.

3. Bring your turbine HVLP system to the job

Turbine HVLP systems are so portable and compact that taking them to the job site a breeze. Whether you need to do a simple touch-up to that newly-installed cabinet which was damaged, or if the job calls for refinishing a set of built-ins, turbine HVLP systems can do the job. As shown in the above photo, when I needed to finish the Murphy bed frame and lacked space in my spray booth, I effortlessly moved my system into the garage where I had more than enough space to finish the job. It worked like a charm.

So there you have it, turbine HVLP systems are a great choice for those looking for a finishing system that truly delivers. They stand out as some of the most flexible and portable options on the market today. However, these characteristics alone only scratch the surface of their success.

Stay tuned for the second of my two-part article where I’ll speak about turbine HVLP systems ease of maintenance, low overspray and where they fit into the production level shop lineup.