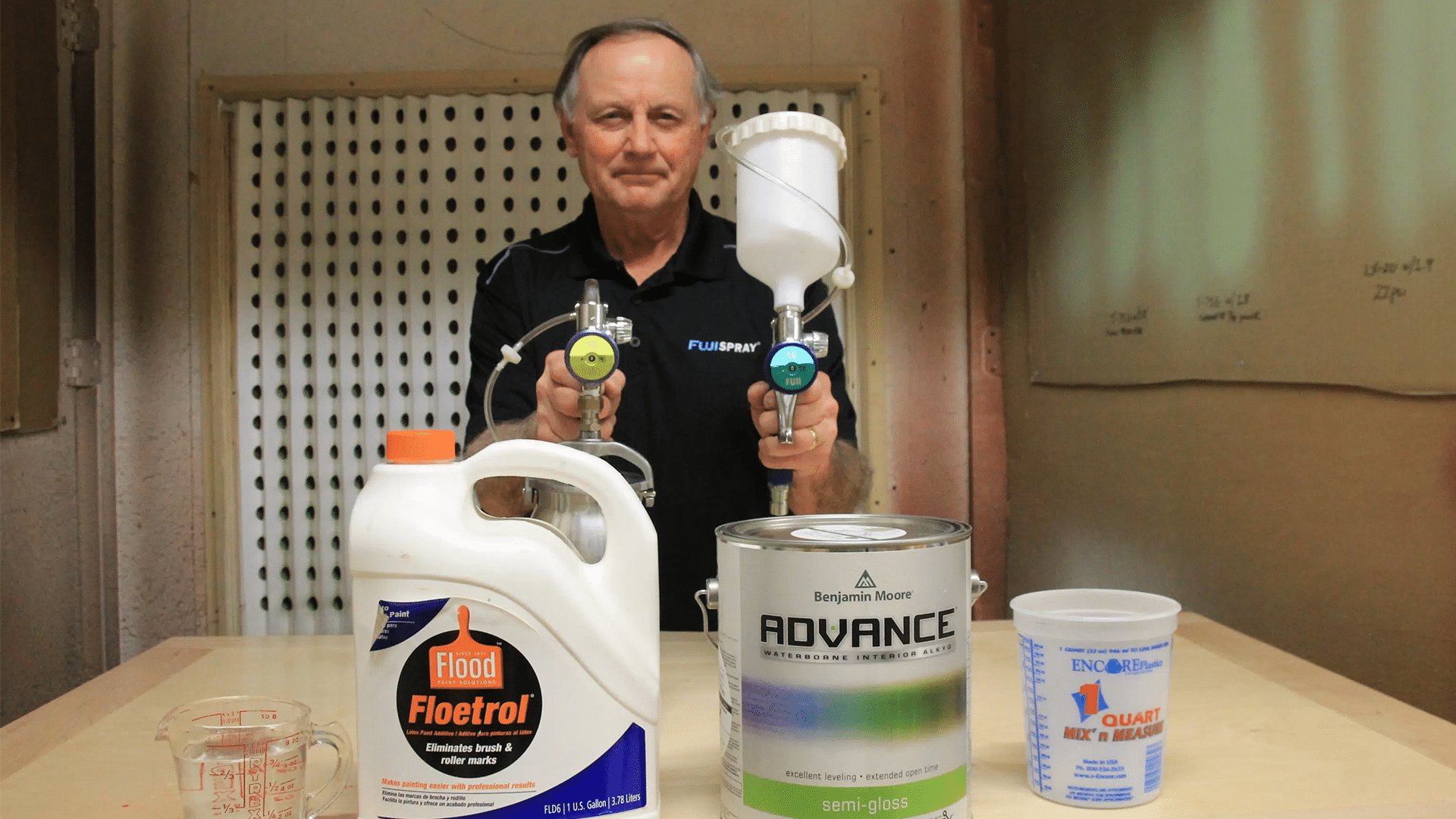

Spraying Benjamin Moore’s Advance

So you want to spray paint, eh?

Today’s modern waterborne hybrid acrylic paints have become one of my favourite go-to finishes for adding colour to my furniture and cabinetry projects. And for good reason: they’re readily available, come in a wide range of colour and sheen, are extremely durable and they spray like a charm. And because of their high acrylic resin content, they outperform latex paints by a wide margin.

In this article I’ll be sharing my approach for getting pro-level results in spraying one of the more popular waterborne hybrid acrylic paints, Advance by Benjamin Moore.

Thinning is needed

Right out of the tin, these thick (the technical term is “high viscosity”) paints need to be thinned for spraying with HVLP equipment. My hard-earned advice on thinning any finish is: only thin when necessary, and with as little thinner as necessary. Because these are waterborne paints, you’ll be thinning them with water. I do a test batch, starting with a 10:1 ratio of paint to water (I use tap water because of the low mineral count in our community water supply), by volume. After a thorough stirring, I’ll measure the viscosity. For HVLP equipment, aim for a viscosity reading of between 35 and 40 seconds when measuring with a Ford 4 viscosity cup.

Pro tip: Once you’re happy with your paint’s viscosity, carefully document the amount and type of thinner used. Believe me when I say it’ll pay you dividends the next time you go to use this product again.

When to use additives, and which one?

I’ve found that if I need to go beyond the 10:1 ratio, the likelihood of getting paint runs and sags – especially when spraying vertical areas – goes up considerably. To counter that, I use a 1:1 mixture of Floetrol and water in lieu of straight water as my thinner. Again, be careful to apply only as little thinner as is necessary to reach the desired 35 – 40 seconds viscosity reading.

The right aircap set

With the finish viscosity properly established, your next step will be selecting an aircap set (an aircap set consists of three parts: nozzle, needle and aircap). As you can see by this chart, the recommended aircap set for Fuji Spray’s turbine-based HVLP spray guns for the high viscosity paint I’m using here, is between 1.5mm and 1.8mm.

Pro tip: If you’re unsure about disassembly and reassembly procedures, check the manual that came with your equipment. And while you’re assembling your spray gun, why not take this opportunity to lubricate it properly?

Adjusting your spray gun

You’re now ready to load your gun (don’t forget to strain the finish!) and adjust the settings on your spray gun for best results. If you need help with this, check out my previous article on this topic.

Pro tip: If you’re still not getting the results you want with any of the previously recommended aircap sets, try moving up to a larger one and see how things work out for you. You could also consider mounting an aircap (without changing the nozzle and needle) that’s one or two sizes larger… or smaller.

Essential steps

Getting great results with today’s modern acrylic paint is no different than with any other finish:

- proper preparation is essential

- on bare wood, or if you suspect a previously finished surface isn’t already properly sealed, consider spraying a primer coat first

A few tips

- when spraying, you’re better off laying down a few, light coats before finishing off with a slightly thicker one

- ensure you read the finish manufacturer’s recommendations related to drying time between coats, as well as the number of coats required

- finally, make sure you properly clean your gun afterwards (it’s as simple as 1, 2, 3!)

Conclusion

I hope that you’ll consider trying out these exciting new finishes to add colour to your projects. You never know what you’ve been missing until you’ve given it a go, right?!

Until next time, keep safe and all the best with your spray finishing. Oh, and feel free to comment on, or ask questions about this article, as well as letting me know of any other topics you’d like to see featured. I’m here for you.

Ralph

Thank you Marty for the great tips on spraying. I use BM Advance for all my trim and cabinet work, and nothing beats the product.