Spraying Clear Topcoat Finishes

There are a lot of products you can spray with a turbine system, so everything from thick paint to polyurethane is possible. Today I want to focus on two clear topcoats in particular… lacquer and shellac.

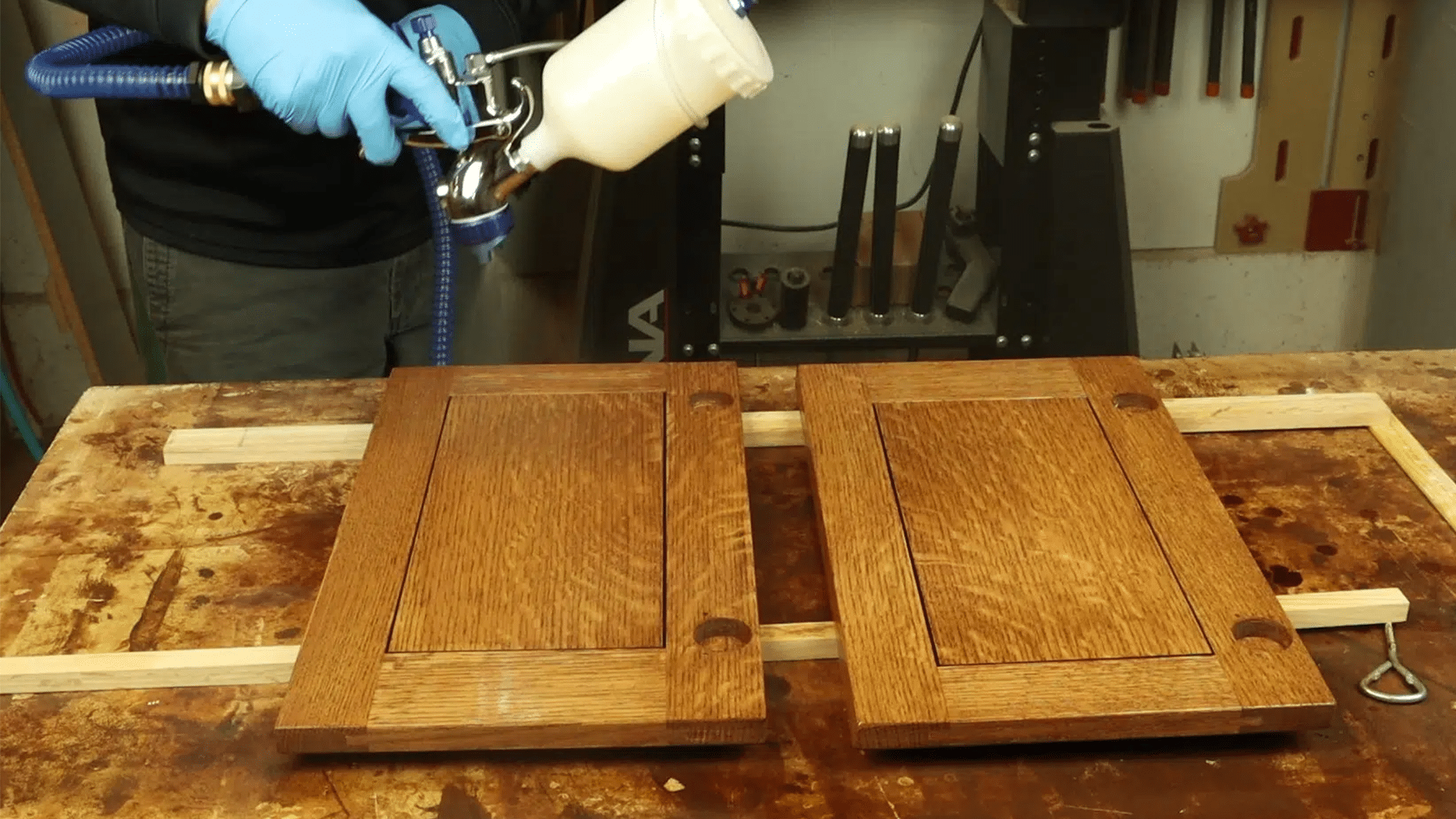

These are two of my favorite finishes for furniture and cabinetry, and for good reason. Let’s start the discussion with lacquer. I spray traditional pre-catalyzed lacquer that thins with lacquer thinner. This vanity was recently re-faced with new doors and drawer fronts using oil-based stain and sprayed lacquer.

The result is a buttery smooth finish that is truly furniture-grade. Follow along through the process of rejuvenating this cute little vanity cabinet with a turbine sprayer.

Pre-catalyzed lacquer comes in a variety of sheens, and for an arts and crafts style cabinet I like to use “satin” lacquer. This sheen is somewhere between “hand rubbed” and “semi-gloss”. It gives the cabinet good protection from the occasional splash of water, yet is entirely fitting for the mission style.

Stir the lacquer well to mix in any sediment at the bottom of the can. The white material you might notice on the end of your stir stick is a compound that modifies the sheen.

As you load your spray gun to start the project, remember this mantra… “Filter Everything that Goes Into the Spray Gun.”

Strain the lacquer, and even the lacquer thinner as you load the fluid cup. This will prevent any potential clogs in the internal filter or spray tip of the gun. Of course, you’ll be donning a respirator with cartridges approved for organic vapors as well.

Lights and Ventilation

Set a number of lights around your work area to illuminate the work. Position them at a low, raking angle for best results. Whenever possible, position yourself so the workpiece is between you and the light. This will let you see the reflection of the wet finish as it’s applied. It seems like a simple point, but is actually key to successful spray finishing.

Don’t forget to work in a well-ventilated area. In a shop setting, this means having a door open with fan running, as well as a garage bay door open for cross-ventilation.

You need lots of horizontal surfaces for spraying, so a little advance thought will help you plan accordingly. I set up two main spraying tables for medium sized projects such as this vanity.

One table has thin strips of lumber to elevate the workpiece as I spray the back surface. Then I’ll flip it over and transfer it to another table that I’ve prepared with painter’s pyramids. I don’t ever set the face of a part on painter’s pyramids, to avoid dents and dings.

Spraying the back of cabinet doors is a quick proposition with a turbine-based spray gun. My favorite spray gun to use is the T75G from Fuji, because I think it’s a little easier to clean than bottom-feed guns.

Overlap your spray pattern by 50% and try to stay reasonably perpendicular to the surface.

Once you flip the cabinet doors over on painter’s pyramids, start by spraying the edges of the rails and stiles.

Your goal is smooth, even coverage, but not too wet on the first coat.

Then proceed to spraying the face of the doors at a roughly perpendicular angle. With doors featuring recessed panels, you get to break the rules a little. Instead of being perfectly perpendicular the entire stroke, you’ll tilt or “whip” the spray gun to get good coverage in the corners and edges. This avoids the typical “rain shadow” where less finish is applied around the recessed edges.

You’ll get the best results if you hold the spray gun 8-10” from the workpiece.

Turbine based HVLP spray guns have so little overspray, you can even refinish the cabinet. Don’t bother removing the cabinet to refinish it, just coat it right where it sits!

In this case, the cabinet needed to be darker than the original golden oak finish, so it was sanded to bare wood and re-stained. Once the stain dried for 24 hours, two coats of lacquer were applied.

Some very light scuff sanding between coats is a good idea, and I usually use soft sanding sponges in the 800-1000 grit range.

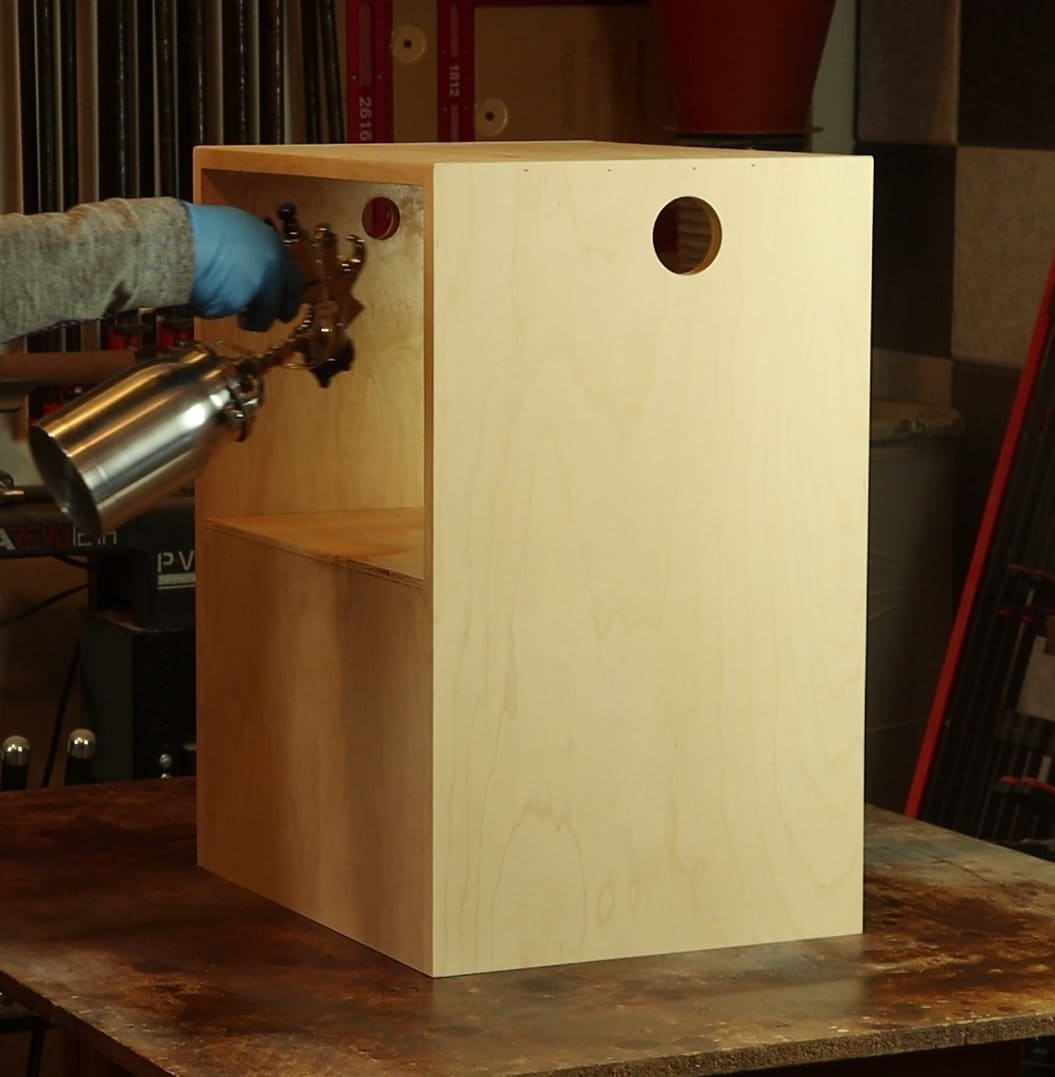

Here’s another small cabinet project that called for shellac as the topcoat. To keep the maple parts white in color, I selected clear shellac. Start with a coat on the bottom surface, then flip the drawers over on painter’s pyramids. Move on to the inside surfaces, and finish with the outside of the drawer.

Usually when spraying many parts, it’s not possible to always hold the spray gun perpendicular to the surface. Luckily, spray finishing is very forgiving, and it will still yield a top-notch finish.

Shellac won’t feel as smooth “off the gun” as lacquer does, however it smooths out nicely with a little scuff sanding.

Additionally, you’ll likely have to wet sand the second coat of shellac for a furniture-grade finish. This usually isn’t the case with lacquer. Since each new coat of lacquer melts into the last, the second coat of lacquer usually requires little or no polishing.

Spraying inside new cabinets presents another set of obstacles. You should plan out the sequence that you’ll spray the cabinet surfaces. I usually start with the bottom, then flip it over. Finally, I’ll work from the inside of the cabinet first, and finish with the more visible outer surfaces.

Spray finishing gives a topcoat that can’t be matched by other methods. If you’re new to spraying, I encourage you to give it a try.

David Stephen

Willie,

Great article, I got lots of information out of this, thank you. Have you written anything about the actual setup of the spray gun? That’s the area I am most perplexed about, any links or info on this subject would be very much appreciated. I have a turbine system as well. Thanks, David

David Stephen

Willie, very good read. I would be keen to have your insights into the actual dialing in or the spray gun. If you have an article on this or so write one- this is the area I need the most advice on. I have a turbine system. Thanks for your time and knowledge.