What Type of HVLP Spray Gun Is for Me?

If you’re new to spray finishing, choosing the right HVLP spray gun may seem like a daunting task. If you simply divide the spray guns into categories, it may make the process easier.

First decide if you want a conversion style spray gun or a turbine-based spray gun. A conversion style spray gun is powered by an air compressor, and the regulator and spray gun convert high pressure to a low-pressure sprayer. By contrast, a turbine system delivers a clean, warm supply of air that is always low pressure.

A compressor driven gun can be a good entry-level choice if you are new to spray finishing. If you choose the right model spray gun, and already have a large compressor, this may be the right fit for you.

If your shop isn’t equipped with a large enough compressor, a turbine system may be the way to go.

Spraying River Boards with an LX-20. If you are leaning towards a compressor powered sprayer, I recommend the Fuji LX-20. It’s available in either a gravity feed or bottom feed version, and delivers the finest finish I’ve seen from a conversion gun. I chose the gravity feed version, because it works well for the type of furniture and woodworking products I spray.

With large, black plastic control knobs, the LX-20 is easy to use, and simple to adjust. Click here to check out all the details on the LX-20 HVLP.

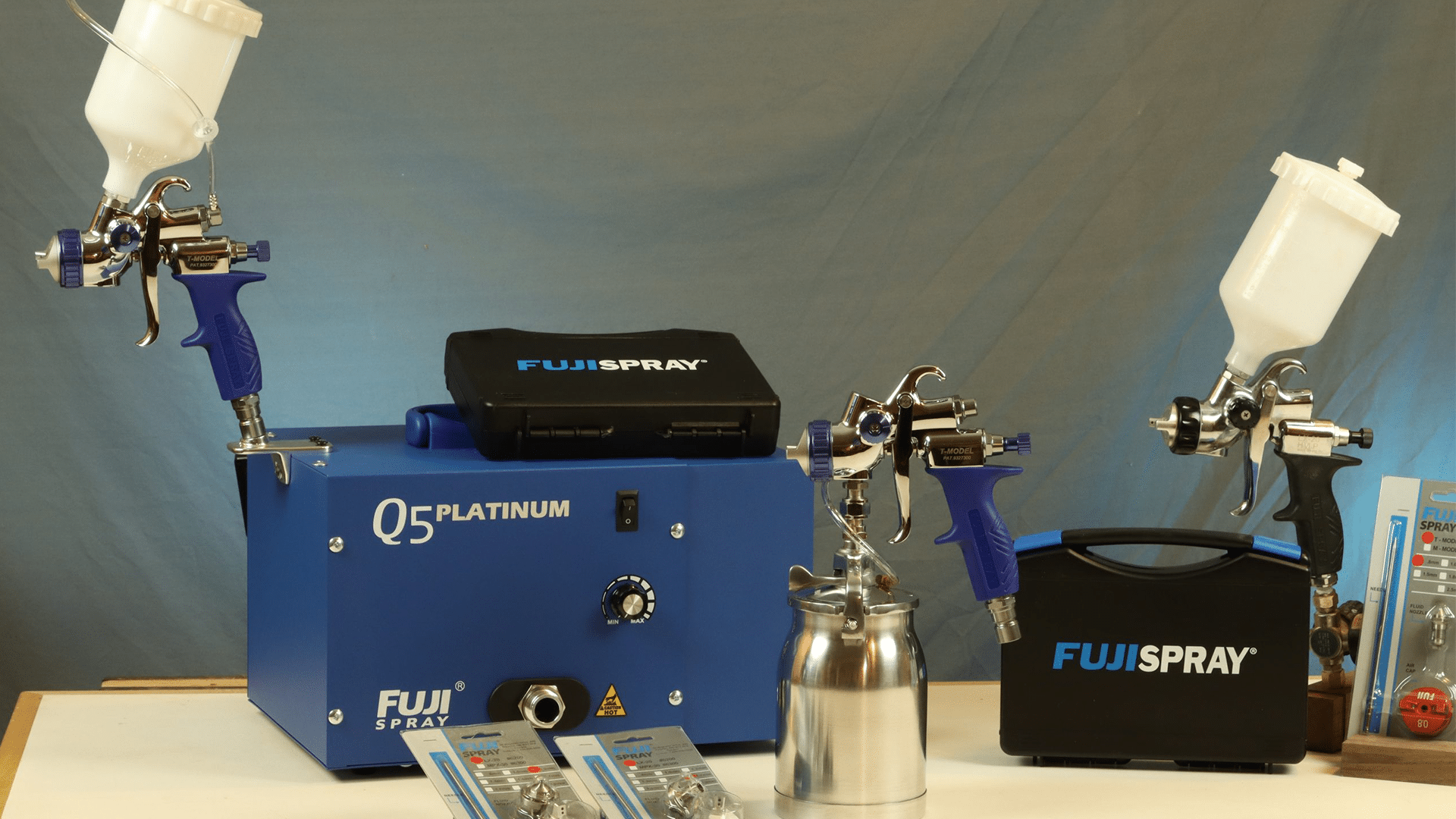

If you’re ready to take the leap into the world of turbine sprayers, you’re in for a real treat. With no air traps, or oily contaminants in the air supply, there are less variables at play. A good turbine system produces a steady supply of warm, low-pressure air for a consistent spray pattern. The very best turbine systems actually have variable speed control, allowing you to dial in the precise amount of air needed.

Even within the category of turbine-based HVLP spray guns, there are some choices to be made. Choose a bottom-feed style spray gun for the extra fluid capacity, and ability to set it down on a workbench between uses. A flexible whip hose is used on turbine guns, instead of the familiar air compressor hose. The clear pressure assist tube on this Fuji T70 spray gun ensures positive pressure for spraying, even if the angle of the gun changes. It’s a classic setup that’s been highly refined to deliver optimal spray pattern.

I spray a lot of furniture and cabinets, and reach for the T70 when I need the extra fluid cup capacity for big jobs. It uses a 900cc cup standard, compared to a 600cc cup for gravity feed guns.

The gun I use most is the nimble T75G gravity feed HVLP. Like the T70G bottom feed gun, the T75G also has pressure assist.

This is a great feature that ensures all of the material is sprayed, down to the last drop. The pressure assist is particularly helpful if your spraying angle is less than optimal. The 600cc cup is good for most medium sized furniture projects, and there’s something I really like about this model. Maybe it’s the fit and finish, or the way is feels in your hand, but I certainly can’t argue with the finish it lays down. You’ll need a gun stand (or two) around the shop, but beyond that I haven’t found any negatives to using a gravity feed gun for most projects.

Spraying small parts with a T75G. Even when I have a small project to spray, I’ll use the turbine.

Set small parts on a turntable, and rotate the pieces to access all surfaces. Usually, I’ll start with the bottom surface, then flip the parts over and place them on painter’s pyramids. From there, I usually work from the inside-out, spraying the inner surfaces first, and finishing with the more visible outer surfaces.

Some woodworkers might ask why I use a turbine to spray such small projects. My answer is always twofold. First, cleaning a gravity feed gun only takes about 2 minutes, and only requires 2 oz. of fresh thinner. The second reason is you just can’t get the same results with a paintbrush or rattle can.

Whatever type of HVLP gun you decide on, whether a bottom feed or gravity feed type, make sure to get one with interchangeable air cap sets.

That way, you can select a smaller 1.0mm air cap for very fine spray, appropriate for thin topcoats like shellac and clear lacquers. Or you can use a medium sized air cap such as a 1.3mm or 1.5mm for general purpose work. Step up to a 1.8mm or 2.0mm tip for thicker paint application.